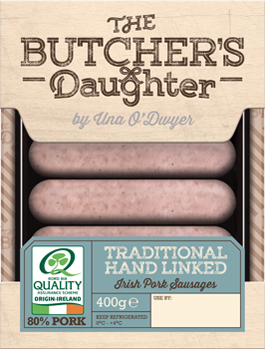

We are really pleased to welcome The Butcher’s Daughter onboard as a new customer; Tipperary’s finest black and white pudding and sausage manufacturer known in the industry for their celebrated and awarded scrumptious gourmet Irish pork range.

With new customers coming onboard and an increase in supermarket supply came the need for Una O’Dwyer, Proprietor of The Butcher’s Daughter to fully computerise her food manufacturing business. Automating tedious, time consuming manual paperwork based order processing, production planning and traceability procedures.

There was a huge requirement to digitize data collection and factory-based controls.

Una chose the NOUVEM Food and Meat Software Solution simply because she felt that we understood her meat processing business. Una could see herself how it was going to benefit her business. We spoke her language – no IT waffle and she could see from the start that we had a solution that actually did solve her problems.

Una wanted a door to door business solution, one which was designed for meat manufacturers and further processors.

The factory management system as demonstrated was easy to follow and easy to understand and Una could see herself using it. She felt that the NOUVEM Food and Meat Software Solution was a perfect fit for her business because of the level of flexibility the system offered and the fact that it could be configured to match the way her business works and that the software is fully scalable.

Implementing The NOUVEM Food Production Software Solution at The Butcher’s Daughter will help Una & her team in the following areas;

- Sales Order Processing – Dispatch – Sales Invoicing – Sage 50 accounts integration

- Purchasing – Goods Receipt – Purchase Invoice – Sage 50 accounts integration

- Production Planning- Production/Manufacturing – Weighing, Labelling & Scanning – Yield and Live Stock Control – Real Time Planning

- Meat Processing – Further Processing Data Capture & Data Reporting

- Recipe Formulation – Maintain Bill of Materials Information – Recipe Batch Control – Scan & Issue Batches of Ingredients & Raw Materials – Ingredients Management – Measuring Ingredients Accurately – Verifying correct quantities of weights to batches

- Automated Quality Assurance & Batch Traceability

- Maintain traceability and product recall consistent with BRC, Bord Bia and HACCP standards

- Manage live stock in all areas, perform stock takes with reconciliation analysis

- Weighing, Labelling & Scanning Stations

- Dispatch Software – mobile and fixed stations for ultimate flexibility

- Reporting including product recall, yield, costings, sales, stock and more

We are really excited to be working with Una & her team and look forward to playing our part in this fantastic success story.